It is a long-standing tradition to discuss the various alloying elements

in terms of the properties they confer on steel. For example, the rule was

that Chromium (Cr) makes steel hard whereas Nickel (Ni) and Manganese (Mn)

make it tough. In saying this, one had certain types of steel in mind and

transferred the properties of particular steel to the alloying element

that was thought to have the greatest influence on the steel under

consideration. This method of reasoning can give false impressions and the

following examples will illustrate this point.

When we say that Cr makes steel hard and wear-resisting we probably

associate this with the 2% C, 12% Cr tool steel grade, which

on hardening does in fact become very hard and hard-wearing. But if, on the

other hand, we choose a steel containing 0,10% C and 12% Cr,

the hardness obtained on hardening is very modest.

It is quite true that Mn increases steel toughness if we have in

mind the 13% manganese steel, so-called Hadfield steel. In concentrations

between l% and 5%, however, Mn can produce a variable effect on the

properties of the steel it is alloyed with. The toughness may either

increase or decrease.

A property of great importance is the ability of alloying elements to

promote the formation of a certain phase or to stabilize it. These elements

are grouped as austenite-forming, ferrite-forming, carbide-forming and

nitride-forming elements.

Austenite-forming elements

The elements C, Ni and Mn are the most important ones

in this group. Sufficiently large amounts of Ni or Mn render

a steel austenitic even at room temperature. An example of this is the

so-called Hadfield steel which contains 13% Mn, 1,2% Cr and

l% C. In this steel both the Mn and C take part in

stabilizing the austenite. Another example is austenitic stainless

steel containing 18% Cr and 8% Ni.

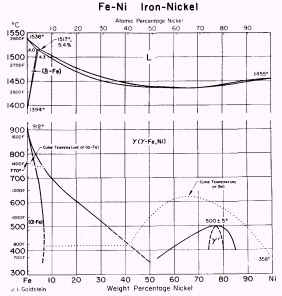

The equilibrium diagram for iron-nickel, Figure 1, shows how the range of

stability of austenite increases with increasing Ni-content.

Figure 1. Fe-Ni equilibrium diagram

An alloy containing 10% Ni becomes wholly austenitic if heated to 700°C.

On cooling, transformation from g to a takes place in the temperature

range 700-300°C.

Ferrite-forming elements

The most important elements in this group are Cr, Si,

Mo, W and Al. The range of stability of ferrite in

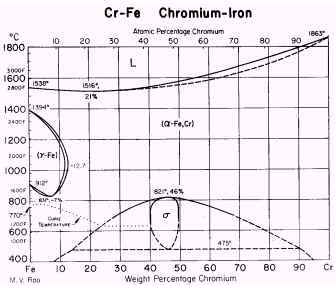

iron-chromium alloys is shown in Figure 2. Fe-Cr alloys in the solid state

containing more than 13% Cr are ferritic at all temperatures up to

incipient melting. Another instance of ferritic steel is one that is used

as transformer sheet material. This is a low-carbon steel containing about

3% Si.

Figure 2. Cr-Fe equilibrium diagram

Multi-alloyed steels

The great majority of steels contain at least three components. The

constitution of such steels can be deduced from ternary phase diagrams

(3 components). The interpretation of these diagrams is relatively

difficult and they are of limited value to people dealing with practical

heat treatment since they represent equilibrium conditions only.

Furthermore, since most alloys contain more than three components it is

necessary to look for other ways of assessing the effect produced by the

alloying elements on the structural transformations occurring during heat

treatment.

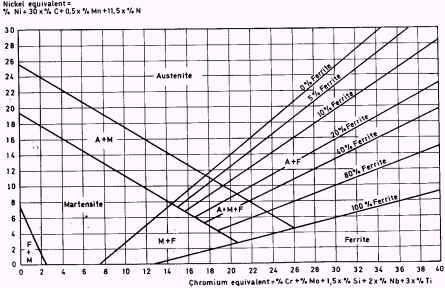

One approach that is quite good is the use of Schaeffler diagrams (see

Figure 3). Here the austenite formers are set out along the ordinate and

the ferrite formers along the abscissa. The original diagram contained

only Ni and Cr but the modified diagram includes other

elements and gives them coefficients that reduce them to the equivalents

of Ni or Cr respectively. The diagram holds good for the

rates of cooling which result from welding.

Figure 3. Modified Schaeffler diagram

A 12% Cr steel containing 0,3% C is martensitic, the 0,3%

C gives the steel a nickel equivalent of 9. An 18/8 steel

(18% Cr, 8% Ni) is austenitic if it contains 0-0,5% C

and 2% Mn. The Ni content of such steels is usually kept

between 9% and 10%.

Hadfield steel with 13% Mn (mentioned above) is austenitic due to

its high carbon content. Should this be reduced to about 0,20% the steel

becomes martensitic.

Carbide-forming elements

Several ferrite formers also function as carbide formers. The majority of

carbide formers are also ferrite formers with respect to Fe. The

affinity of the elements in the line below for carbon increases from left

to right.

Cr, W, Mo, V, Ti, Nb, Ta, Zr.

Some carbides may be referred to as special carbides, i.e.

non-iron-containing carbides, such as Cr7C3 W2C, VC, Mo2C. Double or

complex carbides contain both Fe and a carbide-forming element, for

example Fe4W2C.

High-speed and hot-work tool steels normally contain three types of

carbides, which are usually designated M6C, M23C6 and MC. The letter

M represents collectively all the metal atoms. Thus M6C represents Fe4W2C

or Fe4Mo2C; M23C6 represents Cr23C6 and MC represents VC or V4C3.

Carbide stabilizers

The stability of the carbides is dependent on the presence of other

elements in the steel. How stable the carbides are depends on how the

element is partitioned between the cementite and the matrix. The ratio of

the percentage, by weight, of the element contained in each of the two

phases is called the partition coefficient K. The following values are

given for K:

|

Al

|

Cu

|

P

|

Si

|

Co

|

Ni

|

W

|

Mo

|

Mn

|

Cr

|

Ti

|

Nb

|

Ta

|

|

0

|

0

|

0

|

0

|

0,2

|

0,3

|

2

|

8

|

11,4

|

28

|

Increasing

|

Note that Mn, which by itself is a very weak carbide former, is a

relatively potent carbide stabilizer. In practice, Cr is the

alloying element most commonly used as a carbide stabilizer.

Malleable cast iron (i.e. white cast iron that is rendered soft by a

graphitizing heat treatment called malleablizing) must not contain any

Cr. Steel containing only Si or Ni is susceptible to

graphitization, but this is most simply prevented by alloying with Cr.

Nitride-forming elements

All carbide formers are also nitride formers. Nitrogen may be introduced

into the surface of the steel by nitriding.

By measuring the hardness of various nitrided alloy steels it is possible

to investigate the tendency of the different alloying elements to form hard

nitrides or to increase the hardness of the steel by a mechanism known as

precipitation hardening.

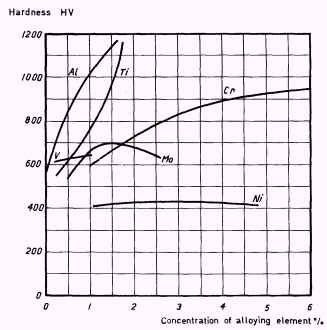

The results obtained by such investigations are shown in Figure 4, from

which it can be seen that very high hardnesses result from alloying a

steel with Al or Ti in amounts of about 1,5%.

|

Figure 4.

|

Effect of alloying element additions

on hardness after nitriding

Base composition:

0,25% C, 0,30% Si, 0,70% Mn

|

On nitriding the base material in Figure 4, hardness of about 400 HV is

obtained and according to the diagram the hardness is unchanged if the

steel is alloyed with Ni since this element is not a nitride former and

hence does not contribute to any hardness increase.

List of Articles - Knowledge Base